Dovetail Launches Virtual Design and Construction (VDC) Department

A 3D scan of a residential home produces a point cloud of the structural systems. This serves as a record of work performed and is used to validate designs in BIM software.

In custom construction, it’s often that the most complicated systems are those that are hidden. It’s the seemingly simple that is actually the most complex to build. Multiple experts and many hands from a variety of building trades come together to complete a project. In preconstruction, the architect and general contractor collaborate to coordinate structural, mechanical, plumbing and electrical engineers. Once on-site, the general contractor manages a diverse array of trades people, carpenters, and artisans. With so many key actors at play, each in their own discipline, with their own set of priorities, it’s crucial to ensure that everyone is coordinated around the same plans and speaking the same language. In big, bold projects, it’s really important to close the gaps between each trade and eliminate as many of the blind spots as possible. This is where virtual construction comes in.

What is VDC?

Collaboration and innovation are at the core of our working process and it’s from this that our in-house Virtual Design and Construction (VDC) team emerged. VDC is the use of advanced technologies to eliminate many common challenges encountered during construction. Coordination and communication are enhanced through the combined use of 3D computer modeling, laser scanning, surveying tools, and CNC routers. Dovetail uses VDC to elevate the entire construction process, producing a more efficient, more effective, and more enjoyable experience for the whole team.

The team gathers around a robotic total station to layout the third floor walls of a new construction residence.

The Process

“VDC is a framework for thinking. It’s a misconception that it’s just a tool and not an application. We consider a project’s needs and its team and apply the appropriate technologies to improve the success of the project. It’s a process that is uniquely applied to every project.”

Identification Phase

For each project, the project manager and superintendent sit down with our VDC manager during pre-construction to discuss the specific needs and considerations. They identify critical constructability issues such as critical path milestones, complicated details, and areas that might benefit from enhanced coordination. A large, complex project might benefit from the use of computer modeling, laser scanning, surveying tools, and CNC routers, while a small project may require only one technology.

Implementation Phase

Once selected, the technologies are built into the construction schedule and site deadlines are set. Addressing an issue in the field, after so many specialties are mobilized, can financially expose clients to costly construction delays and schedule impacts. A study by Building Solutions estimates that change orders, or variations in the agreed upon scopes of work, account for anywhere from 8 to 14 percent of capital construction projects. By shifting the inevitable construction problems to earlier in the design process, we reduce risk and mitigate impacts on schedule and budget.

Execution Phase

Dovetail manages the VCD coordination between architects, engineers, and sub-contractors and engages proactively with issues we see on-site. The technologies we utilize are useful tools to architects and engineers during the design phase, sub-contractors during the coordination process, and even to owners long after the building is complete.

Isac utilizes a robotic total station to layout the structure before framing.

Available Technologies

Computer Modeling

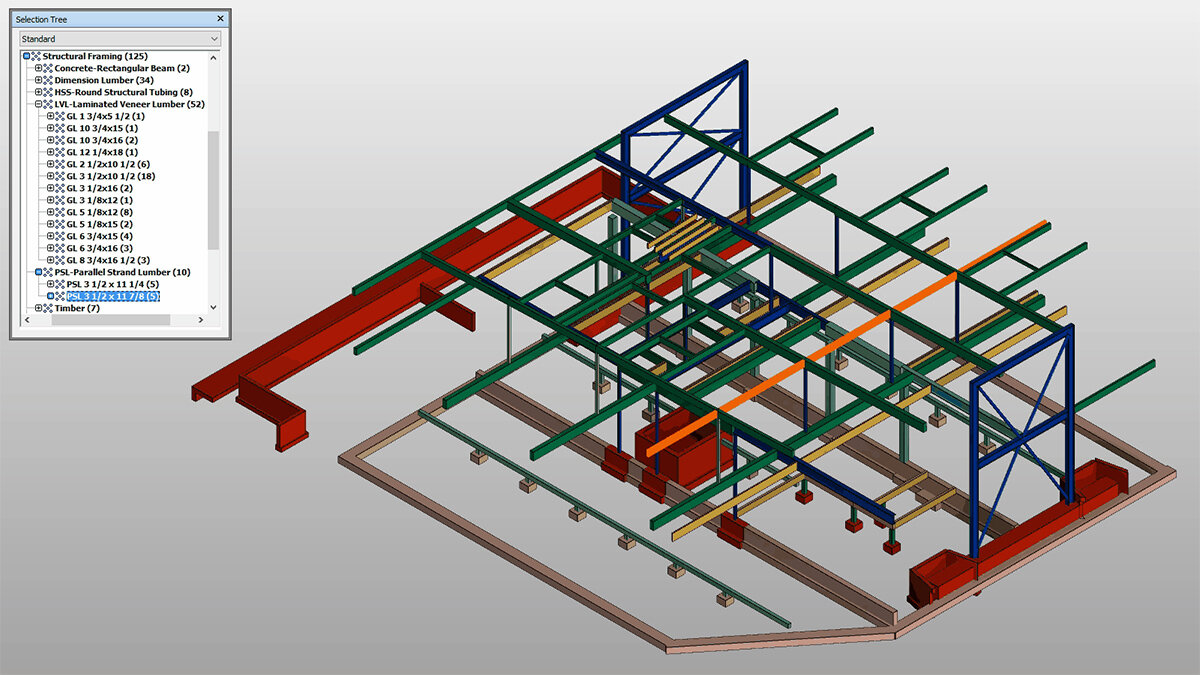

BIM (Building Information Modeling) is a smart 3D model-based process used to design and manage buildings and infrastructures. It allows for multiple team members to simultaneously work on the same project model and has collaborative functions that make sharing project data easy.

Dovetail takes the 3D model from the architect or internally builds the 3D model to enhance coordination and provide clash detection. Previously, we would print out and compare a structural plan set with a mechanical plan set, and it was often difficult to see where the two systems clash. Ethan, our VDC manager, uses the “spot the difference” analogy to explain how we used to search for clashes. By leveraging 3D modeling, it’s obvious when a structural column intersects with a heating duct. Not only does 3D modeling make clash detection easier, the models can be used to generate material square footages for accurate pricing, to generate shop drawings, and to overlay new designs over scans of existing construction.

Laser Scanning

Dovetail uses laser scanning throughout the entire construction process. Laser scans capture 3D spatial data to form a point cloud and combine this information with photographs. This creates an accurate, digital, 3D representation of a space. Scanning greatly benefits tenant improvement and adaptive reuse projects as it allows us to overlay a 3D model of the new design over the existing as-built conditions.

We continue scanning throughout each phase of construction to provide precise documentation of performed work. As different systems are covered by the next building trade, we have the ability to accurately identify where something has been placed in the ground or in the walls. Not only does this benefit our superintendents and carpenters on site, it also allows architects and owners close observation even when not on site and provides them with a level of confidence in our process. The 3D scans can be utilized years after construction is complete. Our owners and service department can refer back to these scans for building repairs and modifications.

Surveying Tools

Robotic Total Stations are optical instruments that create accurate distance measurements and are used in construction, surveying, and civil engineering. We utilize this tool to speed up the process of laying out foundation walls, footings, formwork, die walls, and many other structural elements. This tool increases field productivity and efficiency, reducing the likelihood of delays incurred by errors and rework.

CNC Routers

Our wood shop utilizes a 3-axis CNC machine to create custom casework, clean joinery, and decorative design elements. In the context of VDC, we use the CNC router to create templates and control jigs to aid us during construction. For example, when an architect designs a restaurant, their layout must optimize the placement of kitchen equipment and their required clearances, multiple systems such as electrical, plumbing, HVAC, and fire suppression, all while maintaining efficient, employee pathways from the back-of-house to the front-of-house and creating a pleasing atmosphere to dine in.

We simplify construction by programming the CNC to directly etch the architect's drawings, as well as any needed electrical and plumbing floor penetrations, onto ¼-inch sheets of MDF. These templates are placed on the floor of the install space and remain there throughout construction. Additionally, we build half height walls housing electrical and plumbing with routed out access panels for systems and equipment installation, which reduces the need to core through studs for piping, simplifying install for mechanical, electrical and plumbing subcontractors.

What’s Next for VDC?

Dovetail is continually looking to advance our technologies and systems and right now, the focus is on accessibility. We are uploading all of our 3D scans to a browser based platform, allowing anyone access on a phone or tablet without the need to download software. We are also making our 3D models used in coordination resolution available online for ease of viewing and access, allowing more eyes on the issues at hand. Additionally, we are looking towards augmented reality, an interactive experience that overlays computer generated information over the real-world environment. Overlaying 3D models over existing construction allows for ease of visualization and design interpretation. Dovetail’s core value of transparency and collaboration permeates every level of the construction process.